Mechanical engineering design and services

In the field of mechanical engineering, the team at C&G Engineering Service offer design, revamping, testing and fatigue verification services. Contact the company's professionals in Padua for more information on the various services or to book a consultation.

Services we offer

The staff is able to offer:

- technical consultations;

- design;

- finite element analysis and calculations (FEM-FEA);

- fatigue testing;

- design of prototypes;

- motion studies;

- structural surveys;

- revamping of existing structures.

Mechanical design

The C&G Engineering Service team monitors the evolution of production technologies and components in order to always provide the best solution.

Together with the customer, we immediately identify the objectives to be achieved and propose realistic and competitive solutions in all respects, organising all the various stages of the project in order to achieve maximum results, with particular attention to reducing costs.

In summary:

- identify and understand the client's needs

- propose the best solutions that meet the requirements;

- develop the project in a comprehensive manner with a turnkey solution;

- develop the project with the customer's technicians.

Completed projects

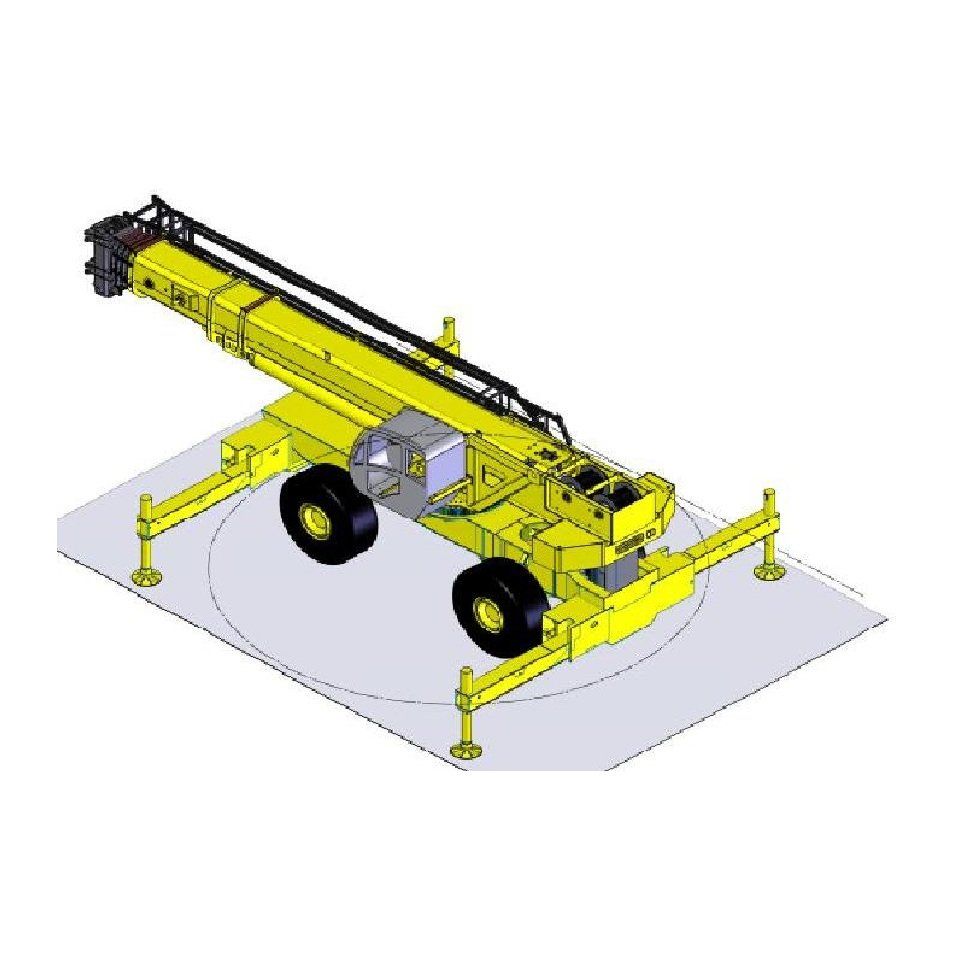

- 80-tonne off-road crane.

- Set design for La Scala mobile theatre in Milan.

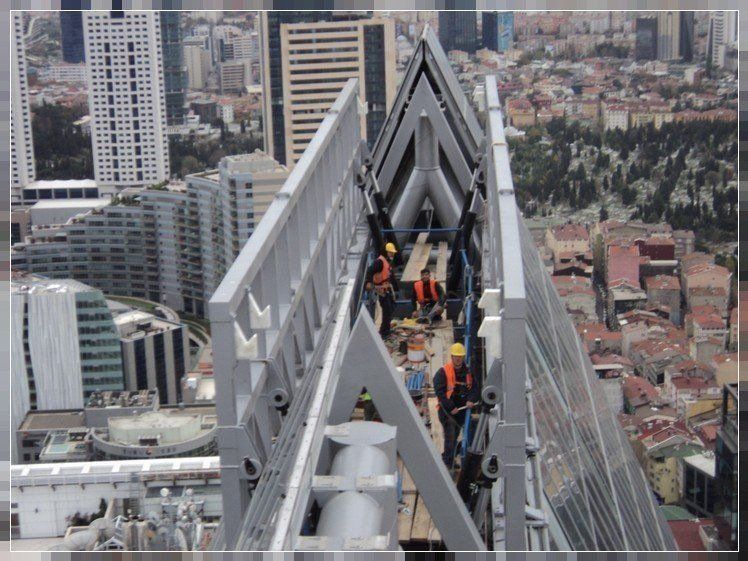

- Soyak Krystal sunroof.

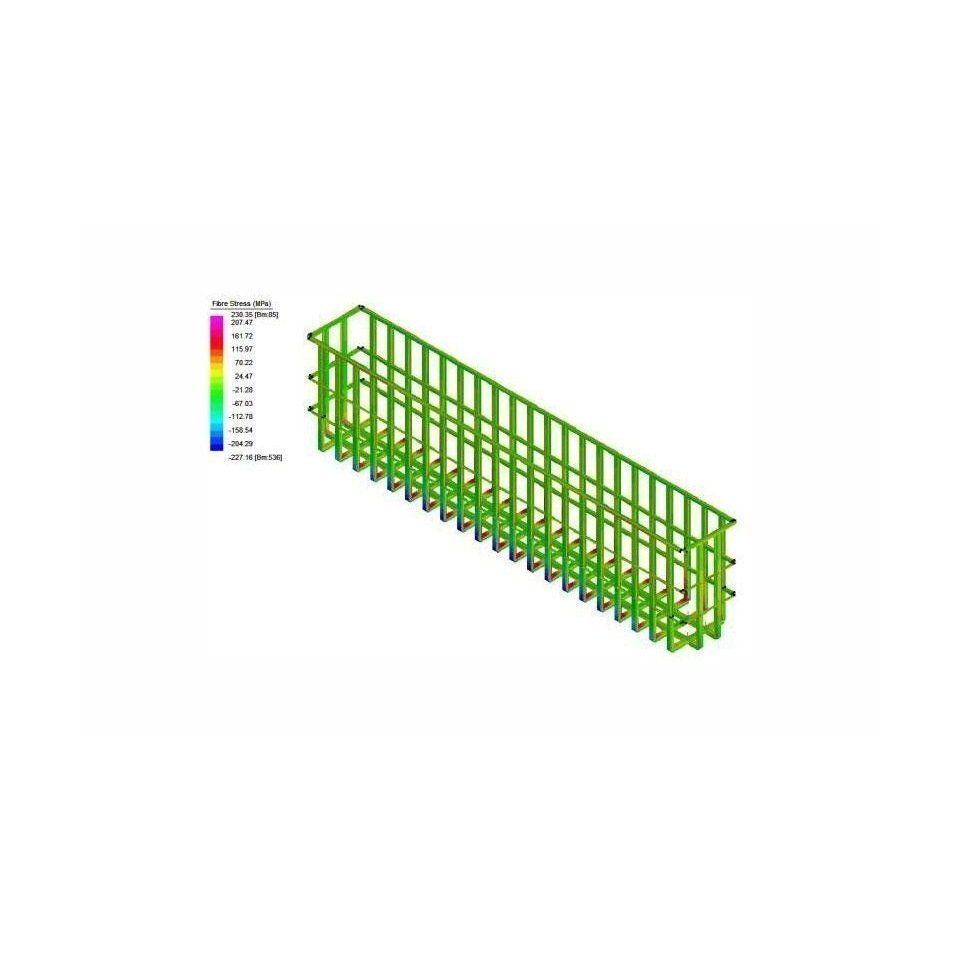

FEM modelling - Kineto-dynamic analysis

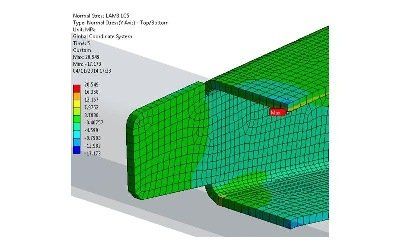

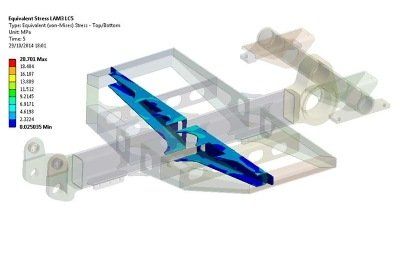

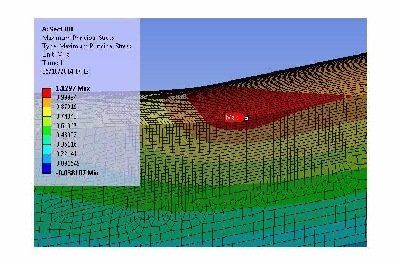

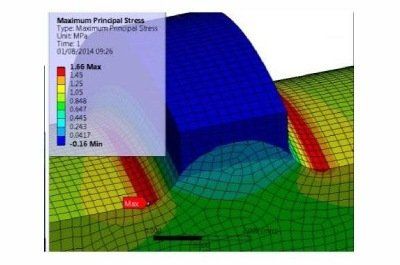

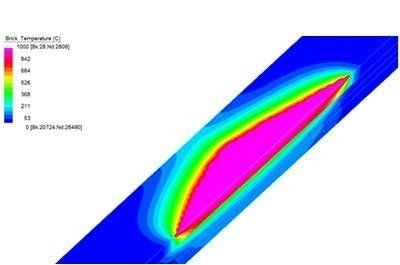

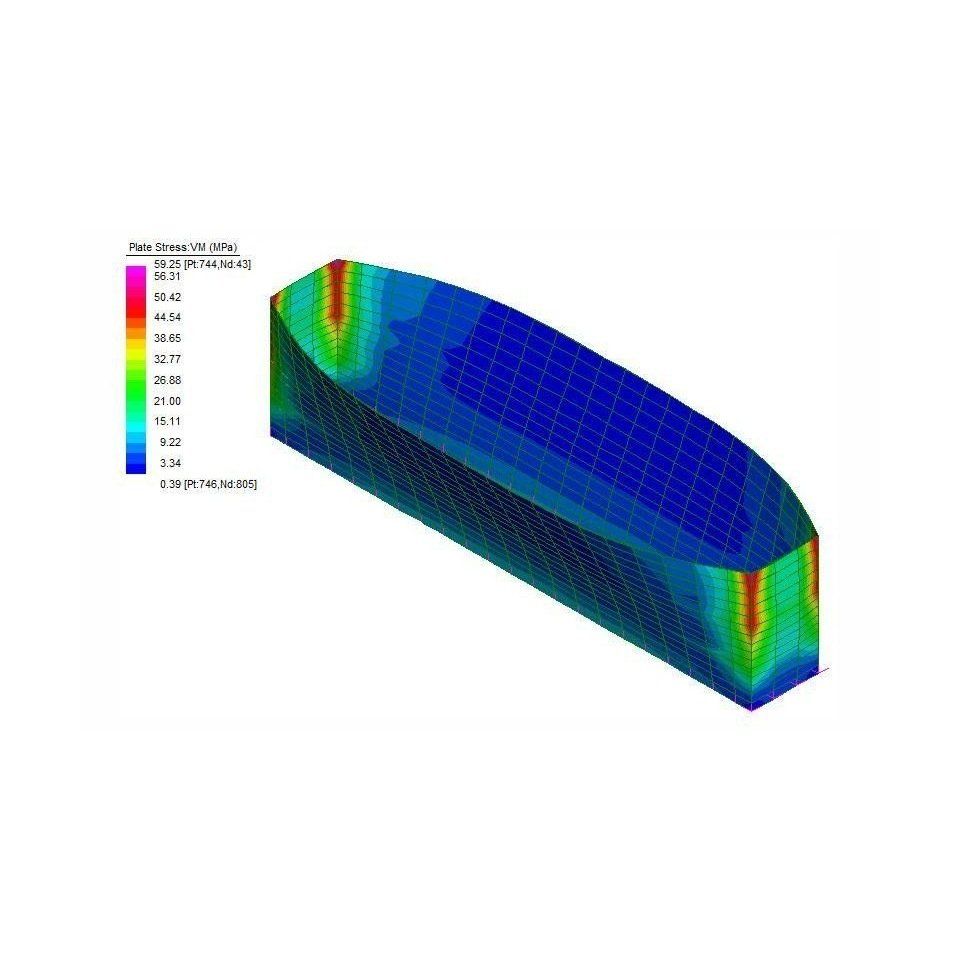

For reducing production costs and improving performance. Through the use of structural calculation programs with finite elements, such as FEM/FEA analysis, optimised geometries are defined in the preliminary phase, which can allow a reduction in production costs and an improvement in performance.

The simulation of structural behaviour allows to reduce the number of preliminary tests on the building and to create optimised prototypes.

FEM/FEA (Finite Element Analysis) analysis not only makes it possible to know what stresses the part to be built will be able to withstand, but at the same time makes it possible to anticipate any problems that may arise. Through structural analysis, it is possible to simulate a specific event and trace the causes of unforeseen failure in order to act in advance on the safety of particular structures.

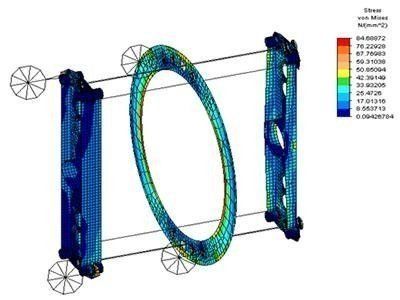

FEM examples - Tension analysis

The following are examples of stress analysis, fatigue testing and high temperature behaviour.

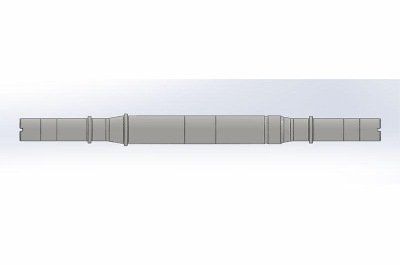

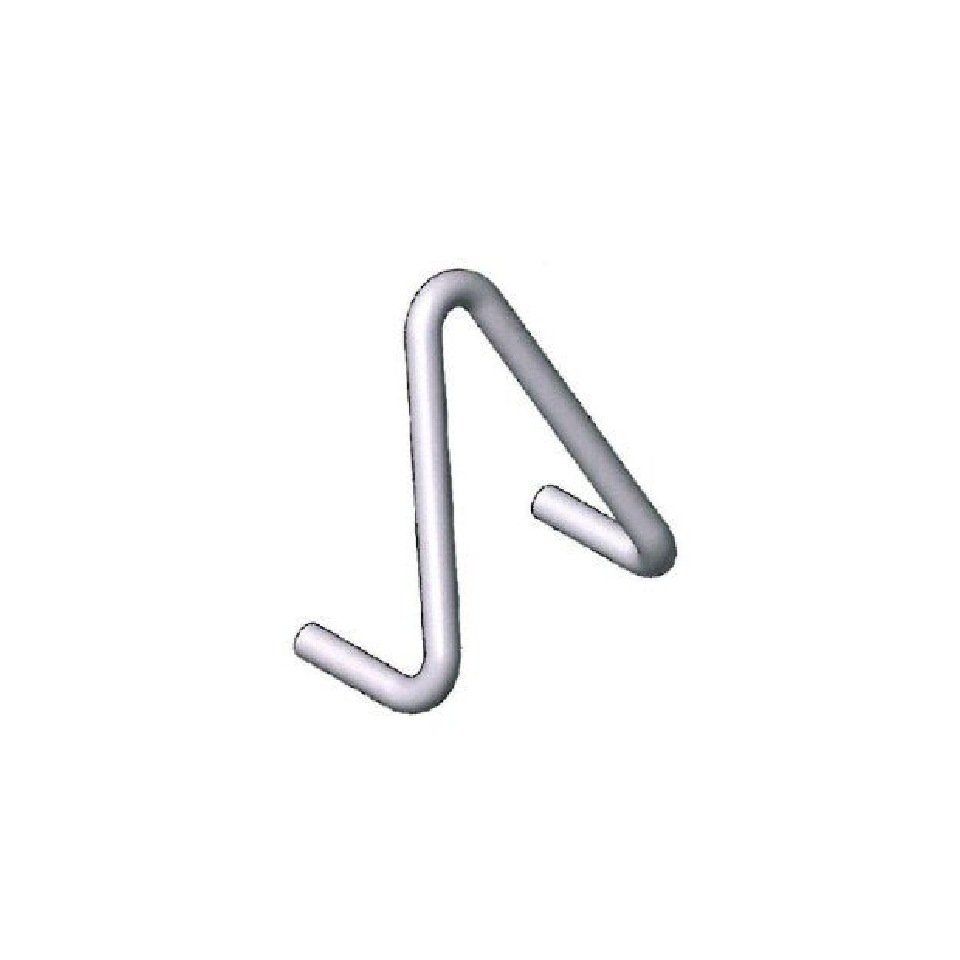

Fatigue testing

Determination of notch coefficients.

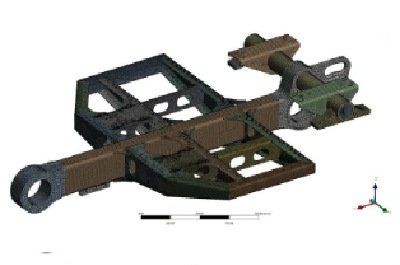

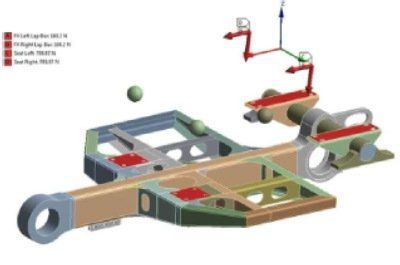

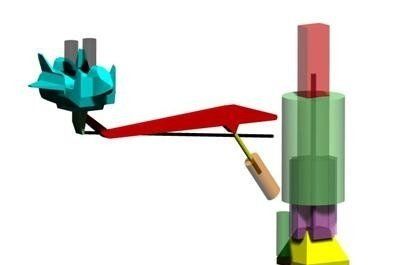

Chassis Vehicle Roller Coaster

Coaster J2SK.

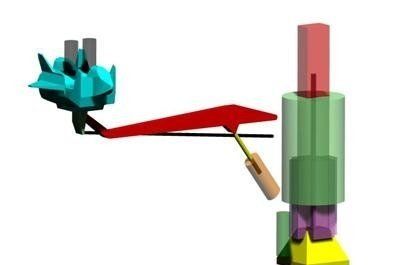

Studying motion

C&G Engineering deals with the study of motion and kinetic-dynamic analyses to study and calculate the kinetic and dynamic properties of systems.

Safety of special equipment and installations

CE marking is the formal act by which the manufacturer certifies that he has fulfilled all the necessary requirements of the Machinery Directive and other important European directives applicable to the machine in general in order to make it safe to use.

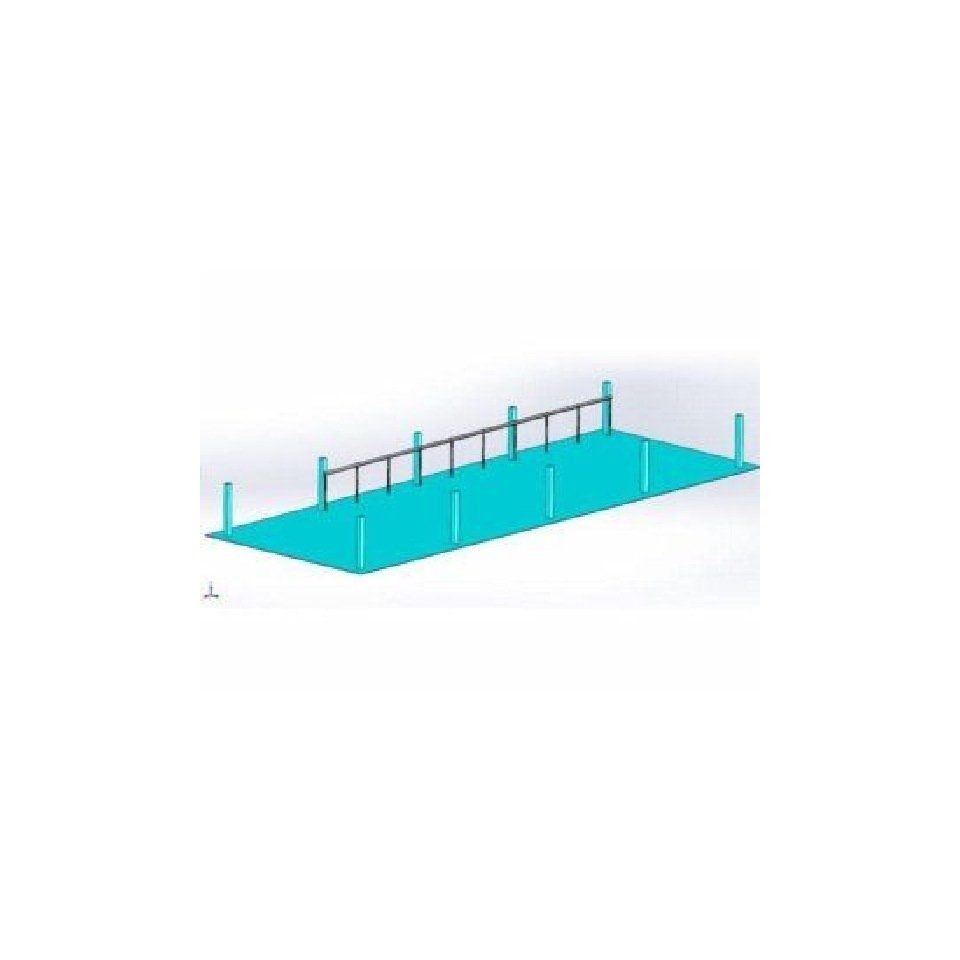

Safety of lifting equipment

Lifting equipment

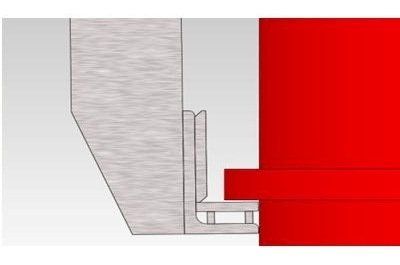

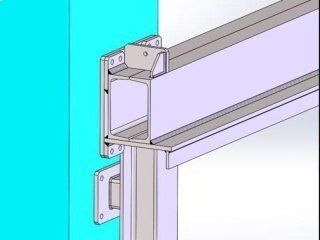

LYTO'S - 13414 Raceway design

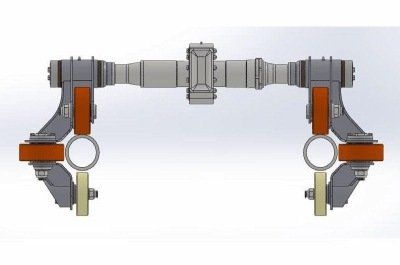

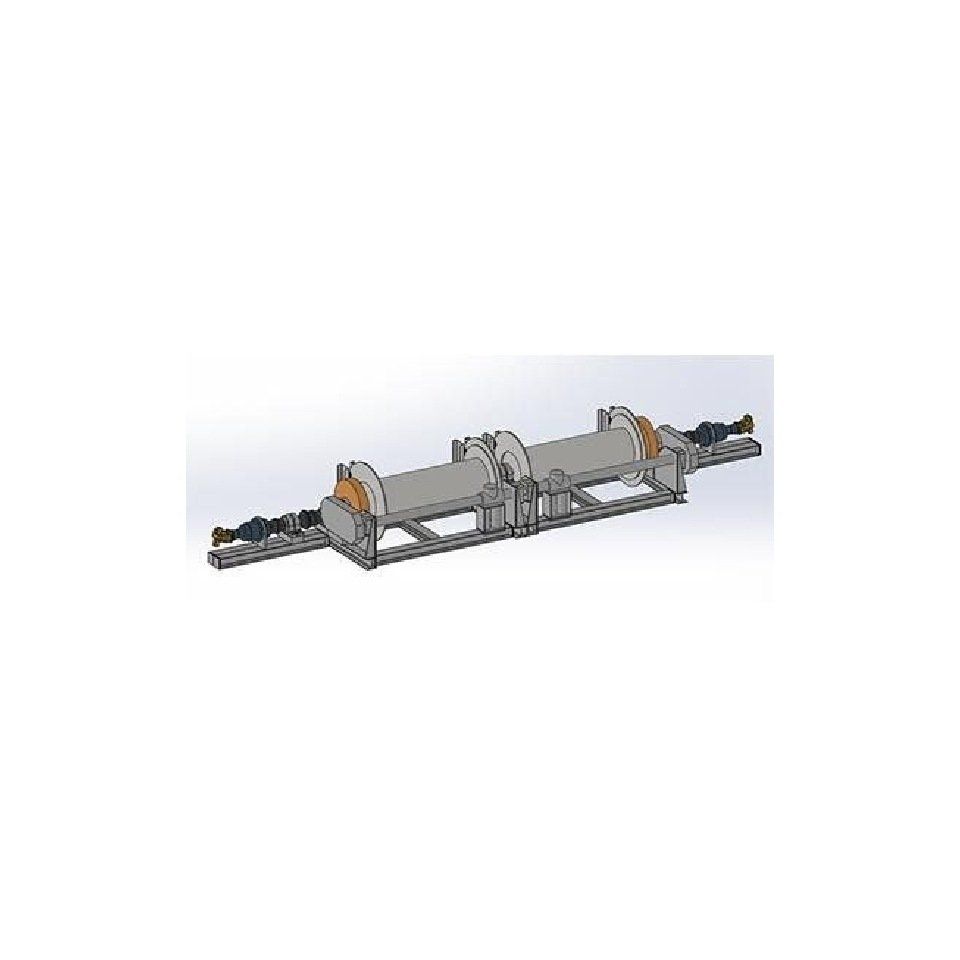

Double winch design for offshore applications

Double drum mooring winch - Max Pull 40 Tons.

Drum capacity: 800 m rope ? = 52 mm.

Variable speed: 0÷40 m/min.

Maximum pull speed: 15 m/min.

Tecnologie Industriali Srl - Design of a double winch.

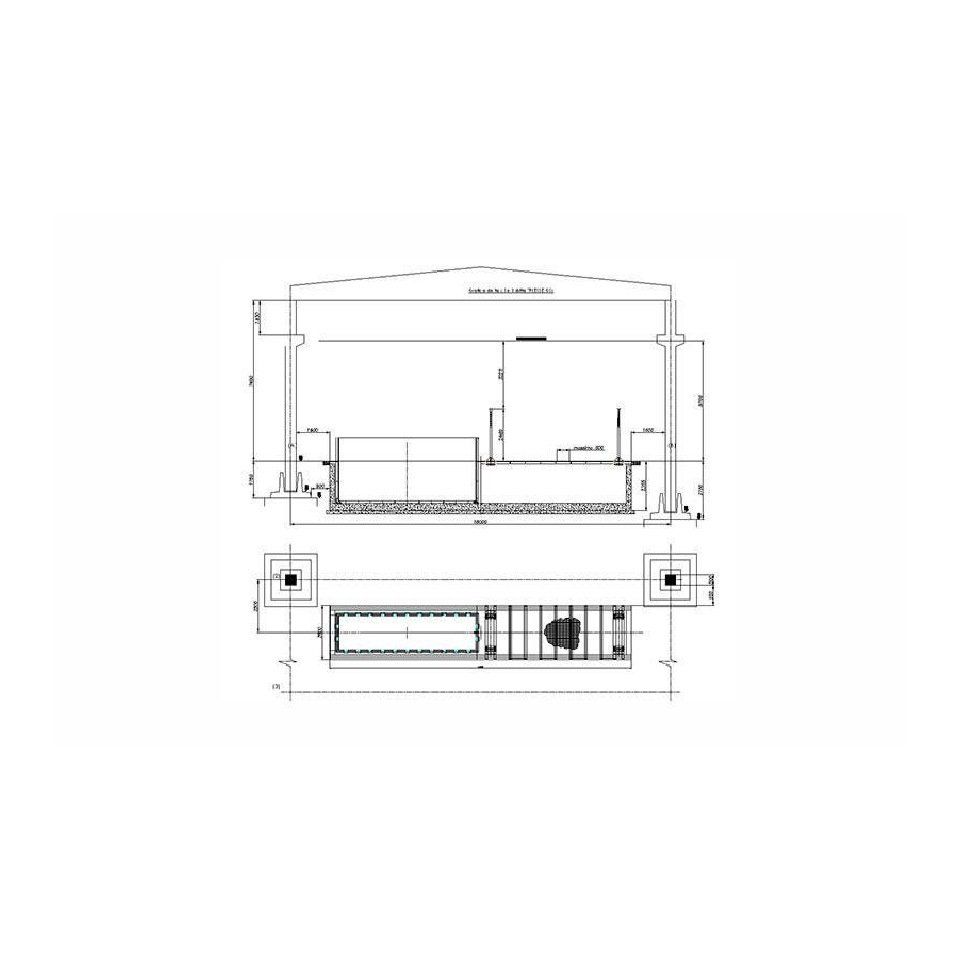

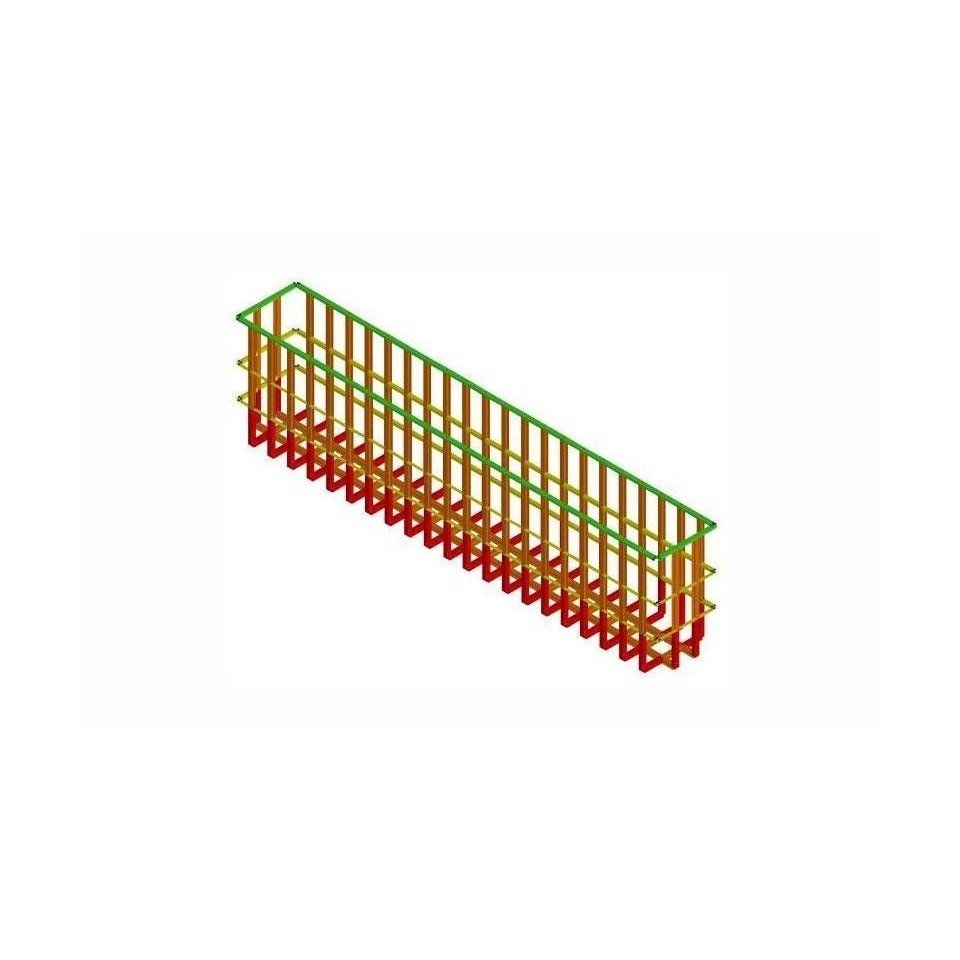

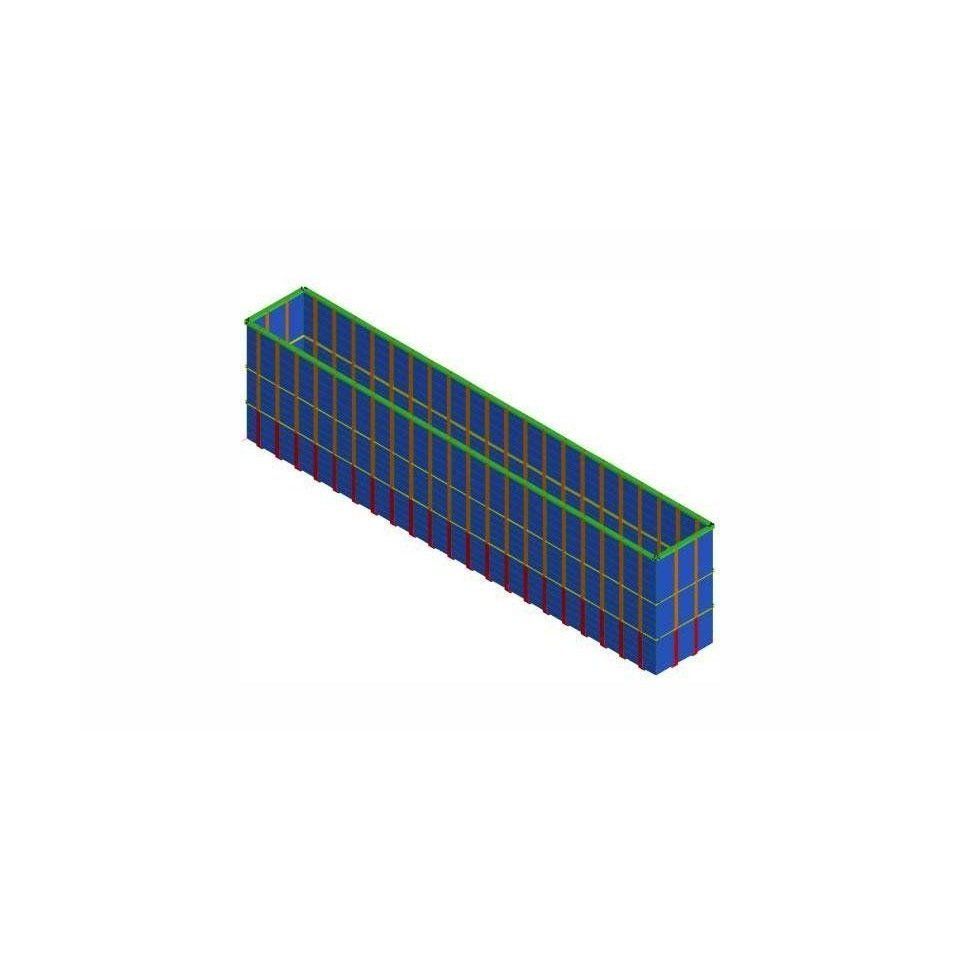

Metal and mechanical carpentry design

The load-bearing structure of an industrial building (shed, silo, hangar, warehouse) is built using profiles and other standardised steel products of suitable dimensions.

The design of the structure is then performed and the drawings for supply, workshop and assembly are drawn up, complete with estimates for materials and calculation reports.

Prototypes

From idea to project with predefined costs: the advantages of design

The company takes care of the analysis and preliminary development of a project for the design and manufacture of new machines, with the aim of achieving cost certainty. The use of calculation programs provides solutions and avoids inconveniences in implementation. Innovation is facilitated because different solutions can be simulated quickly and safely.